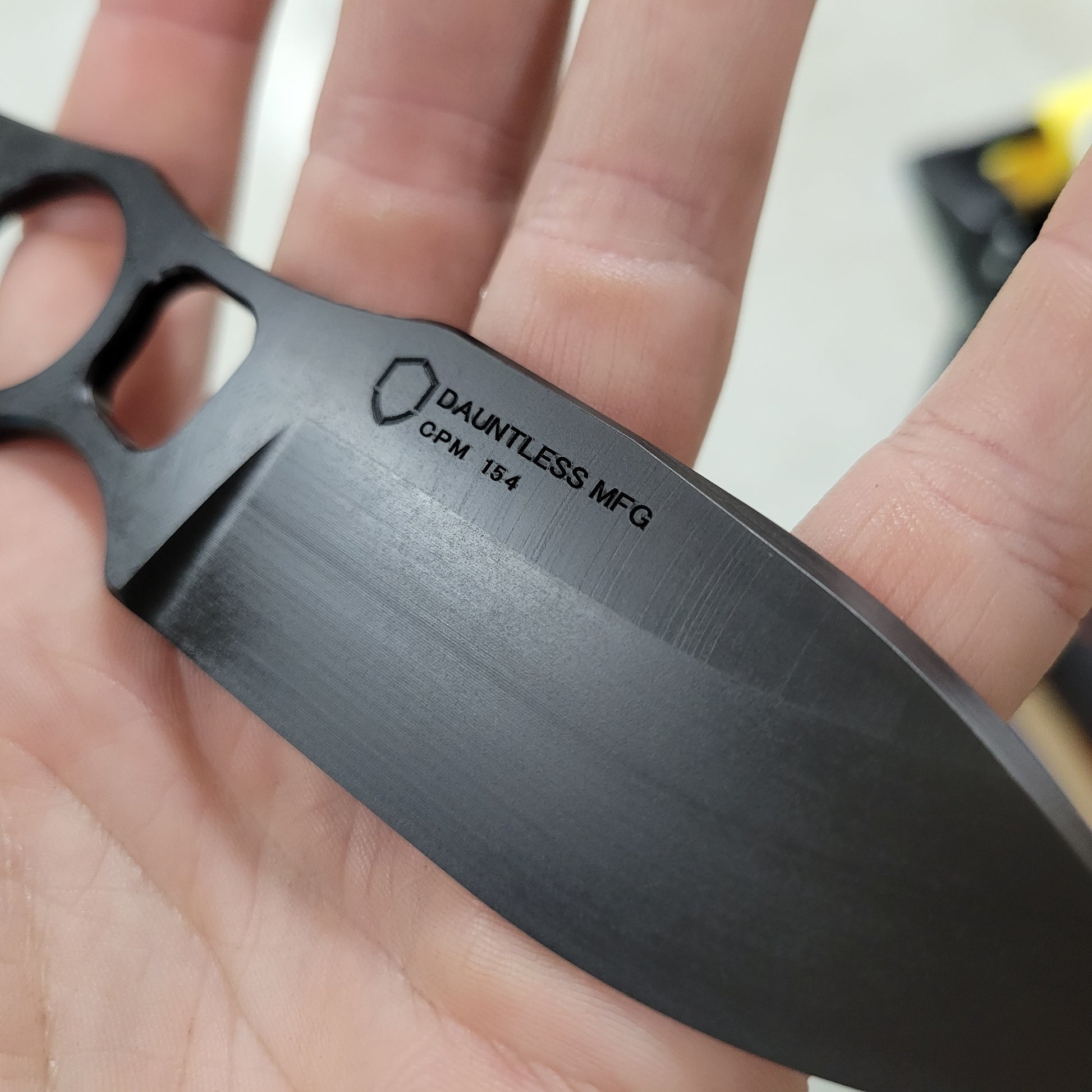

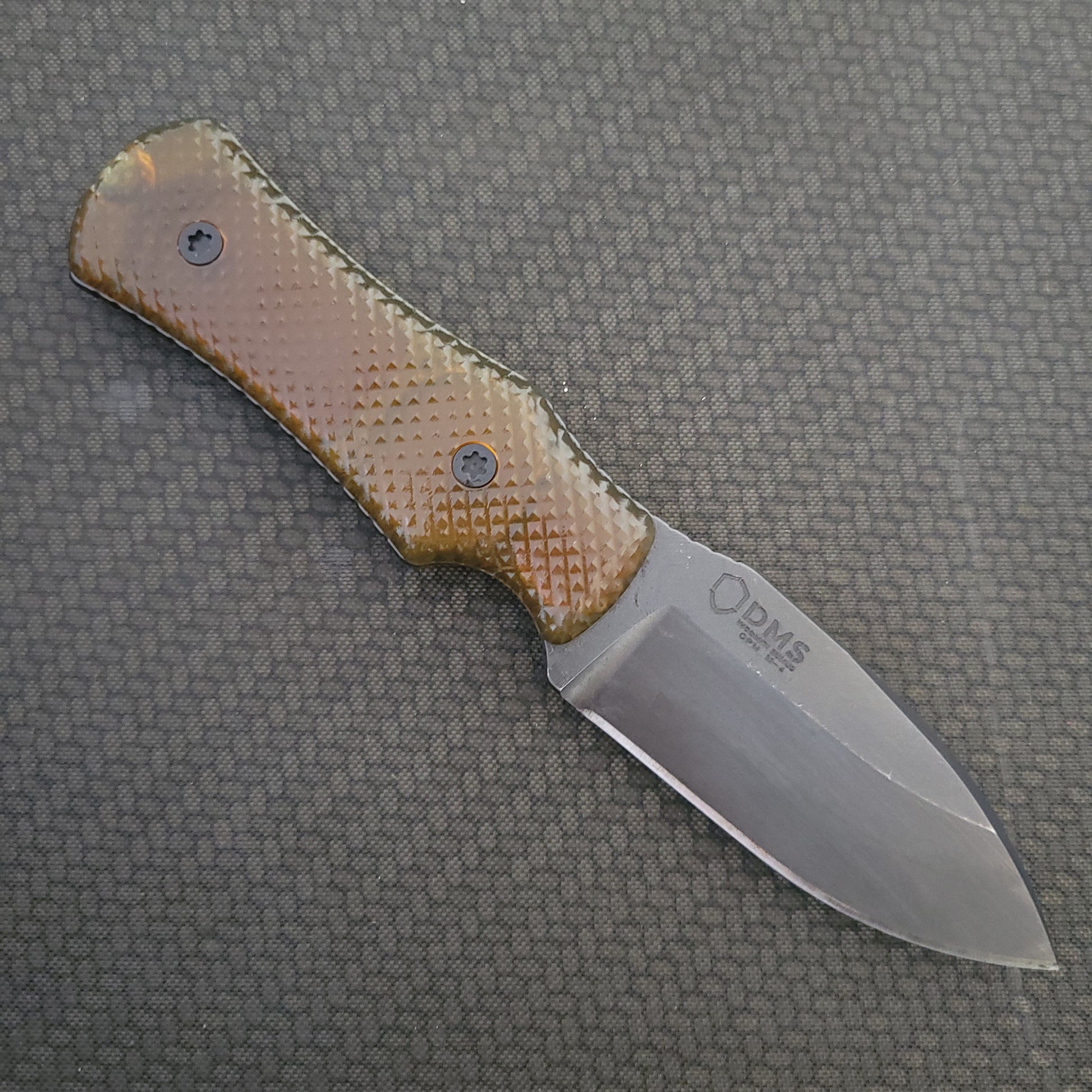

Dauntless Manufacturing

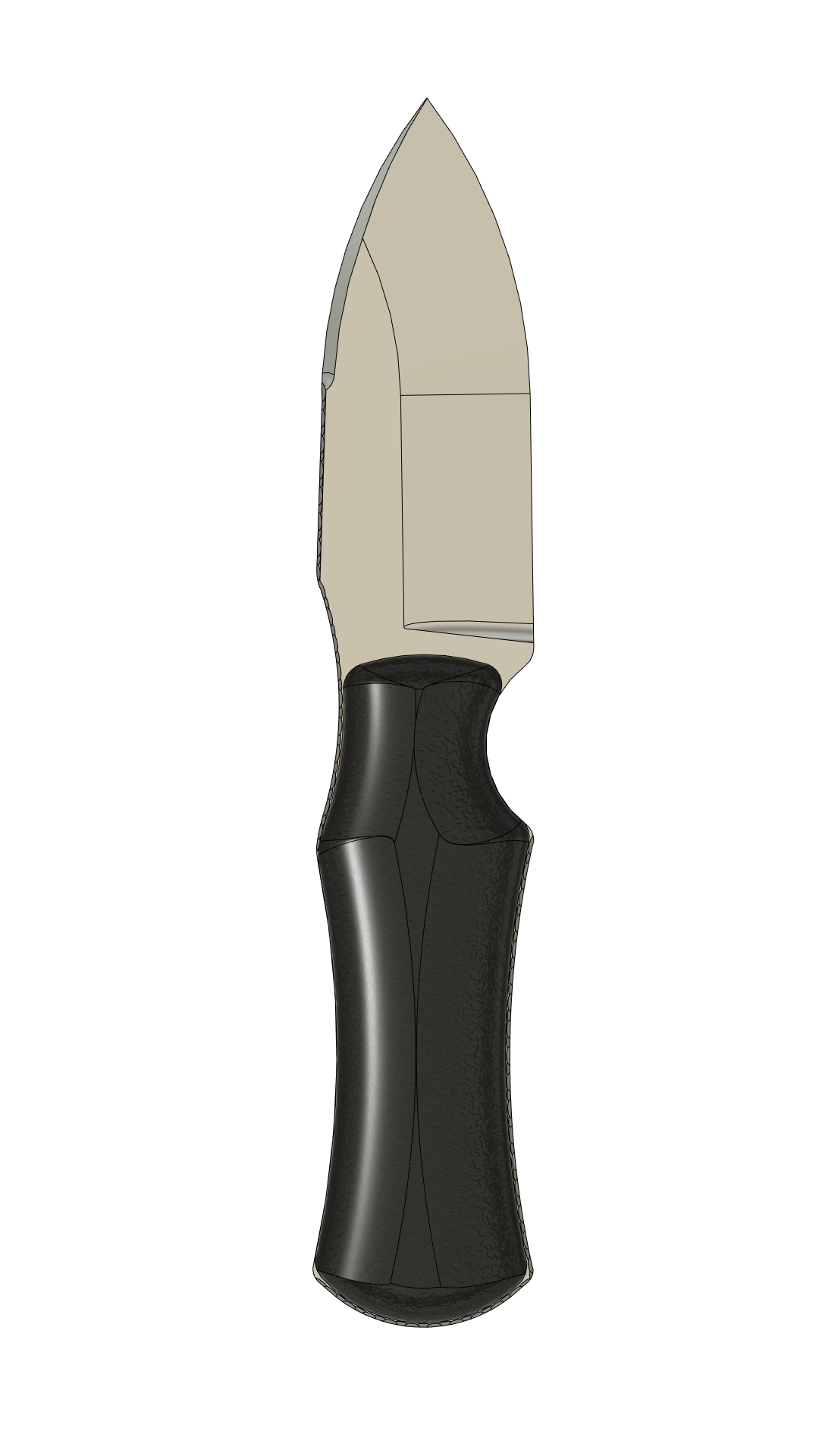

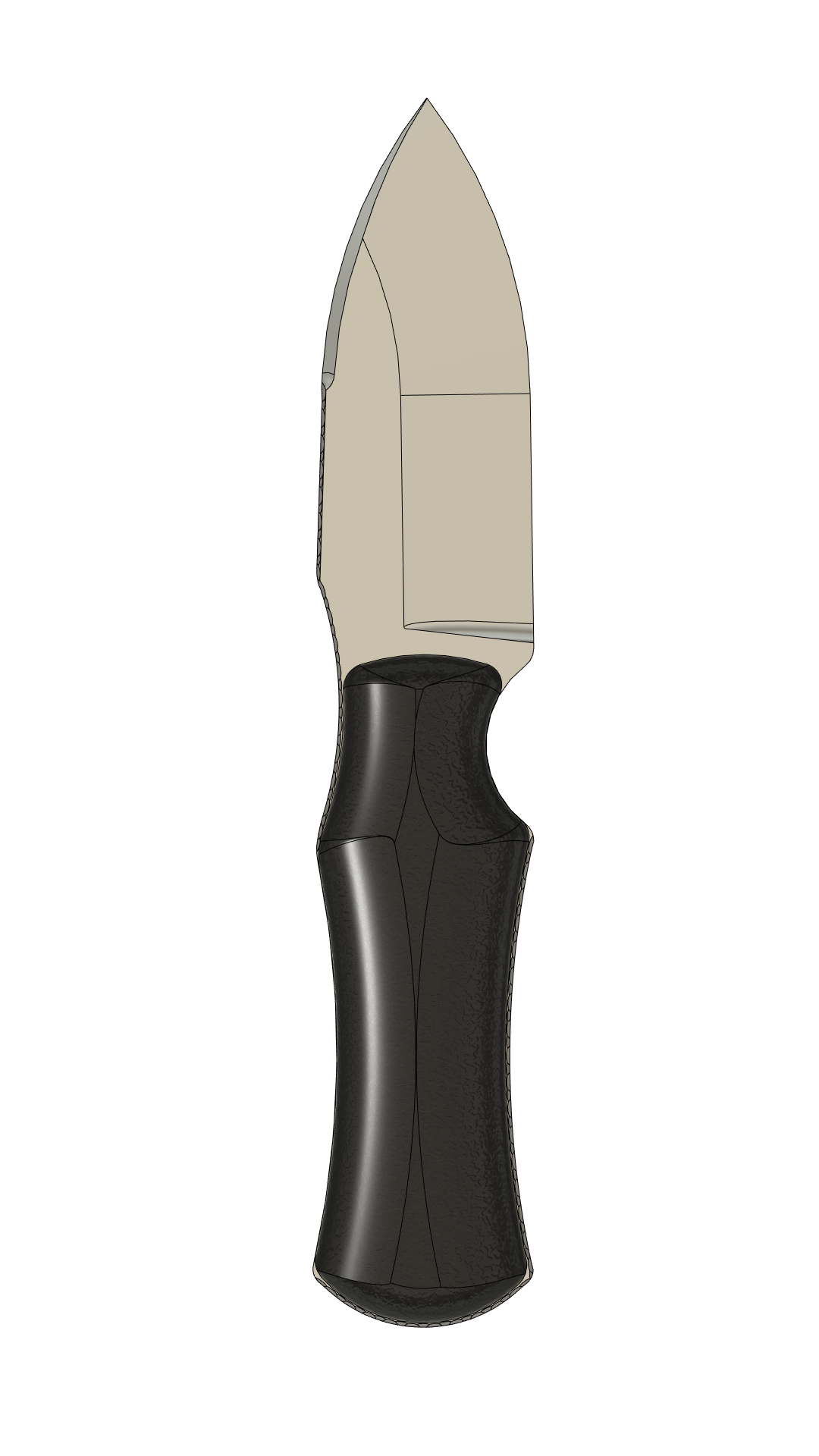

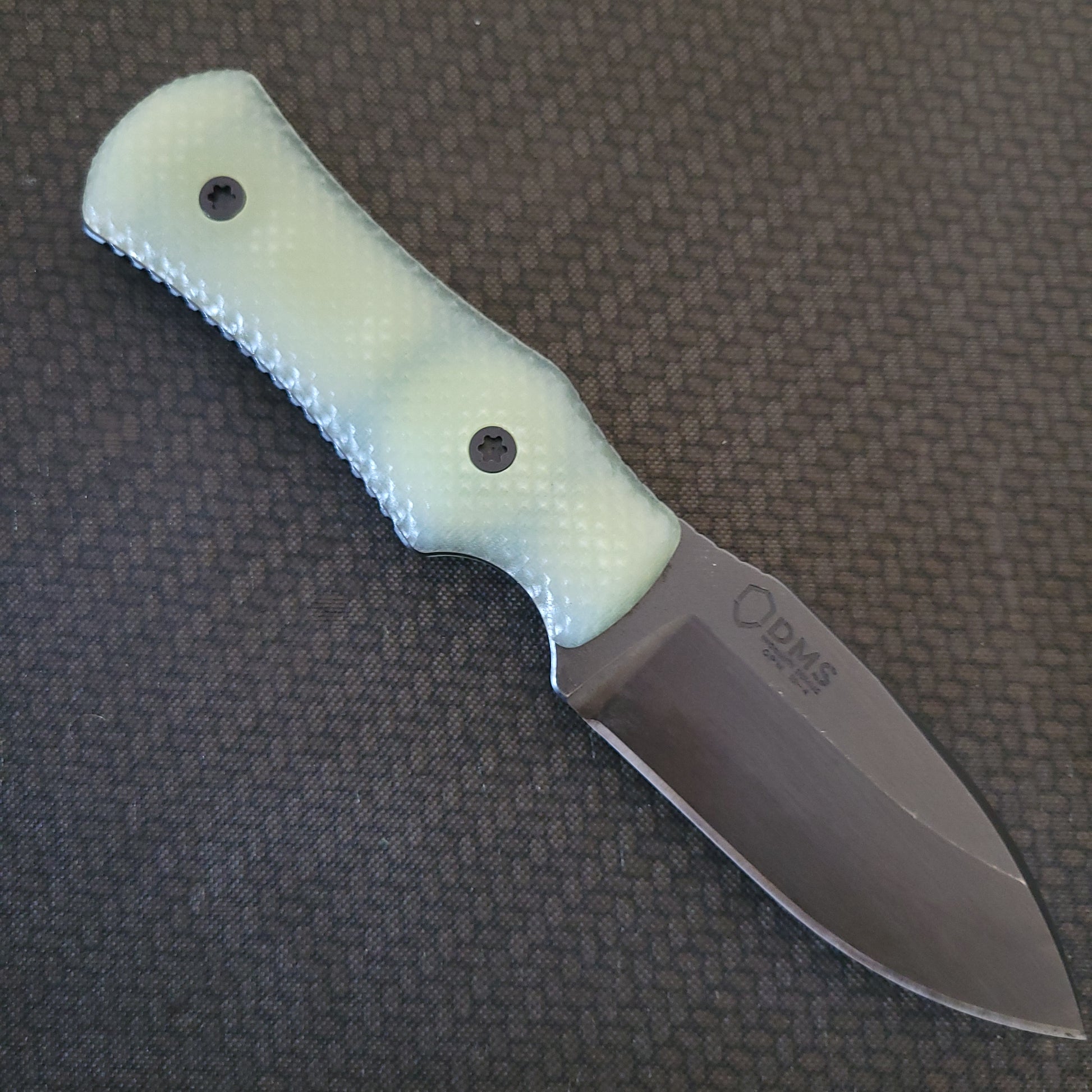

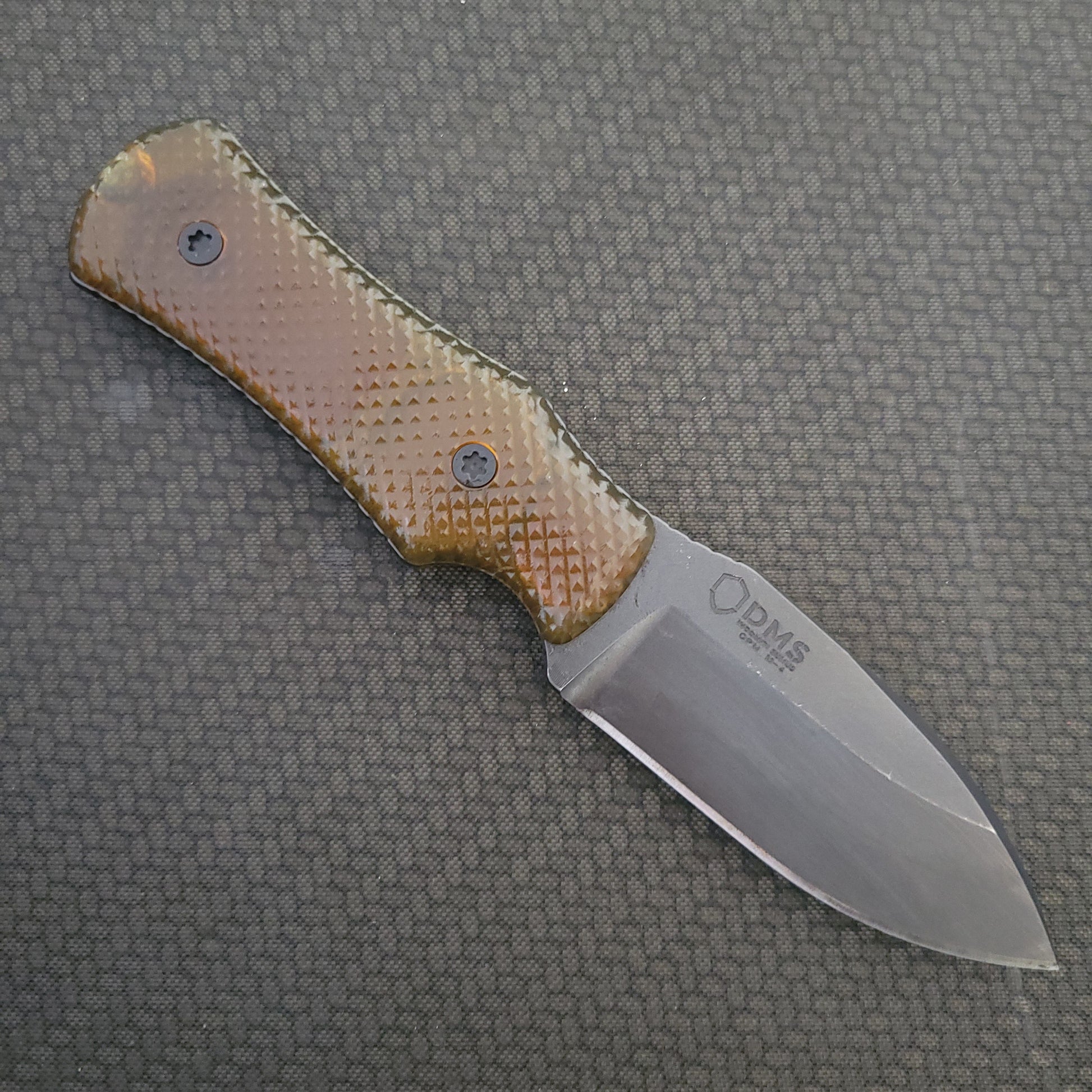

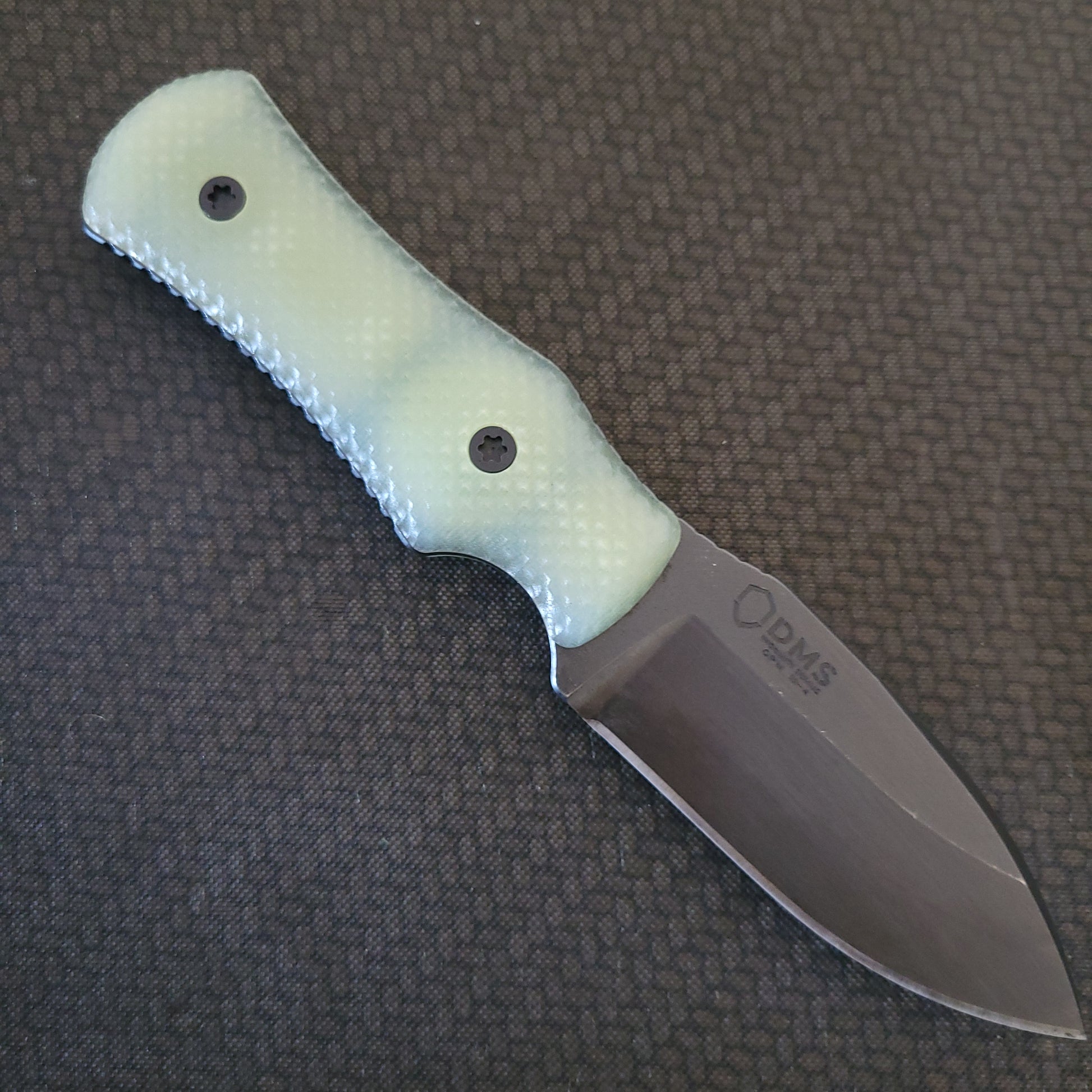

Matt Helm Dogbone

Couldn't load pickup availability

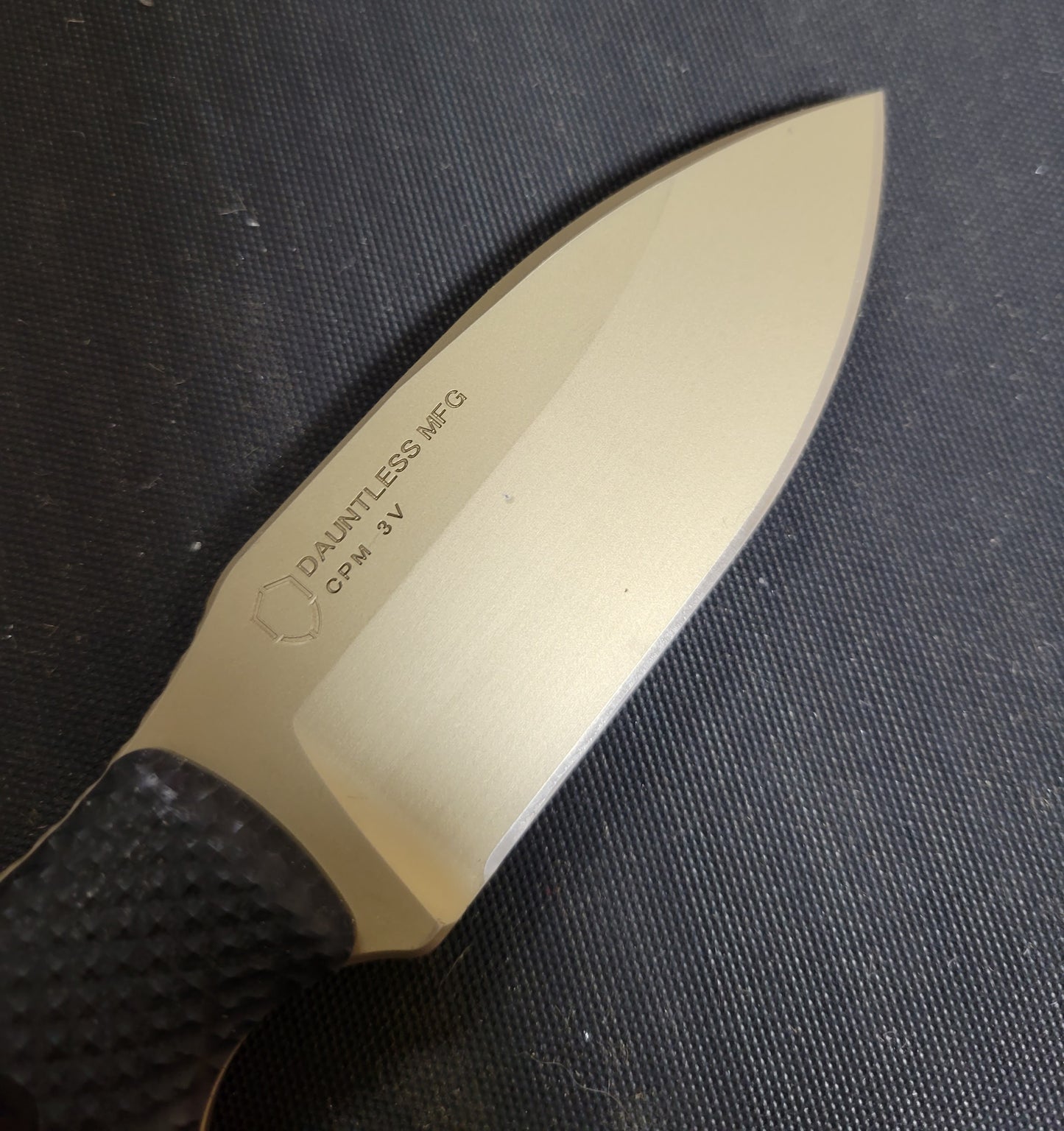

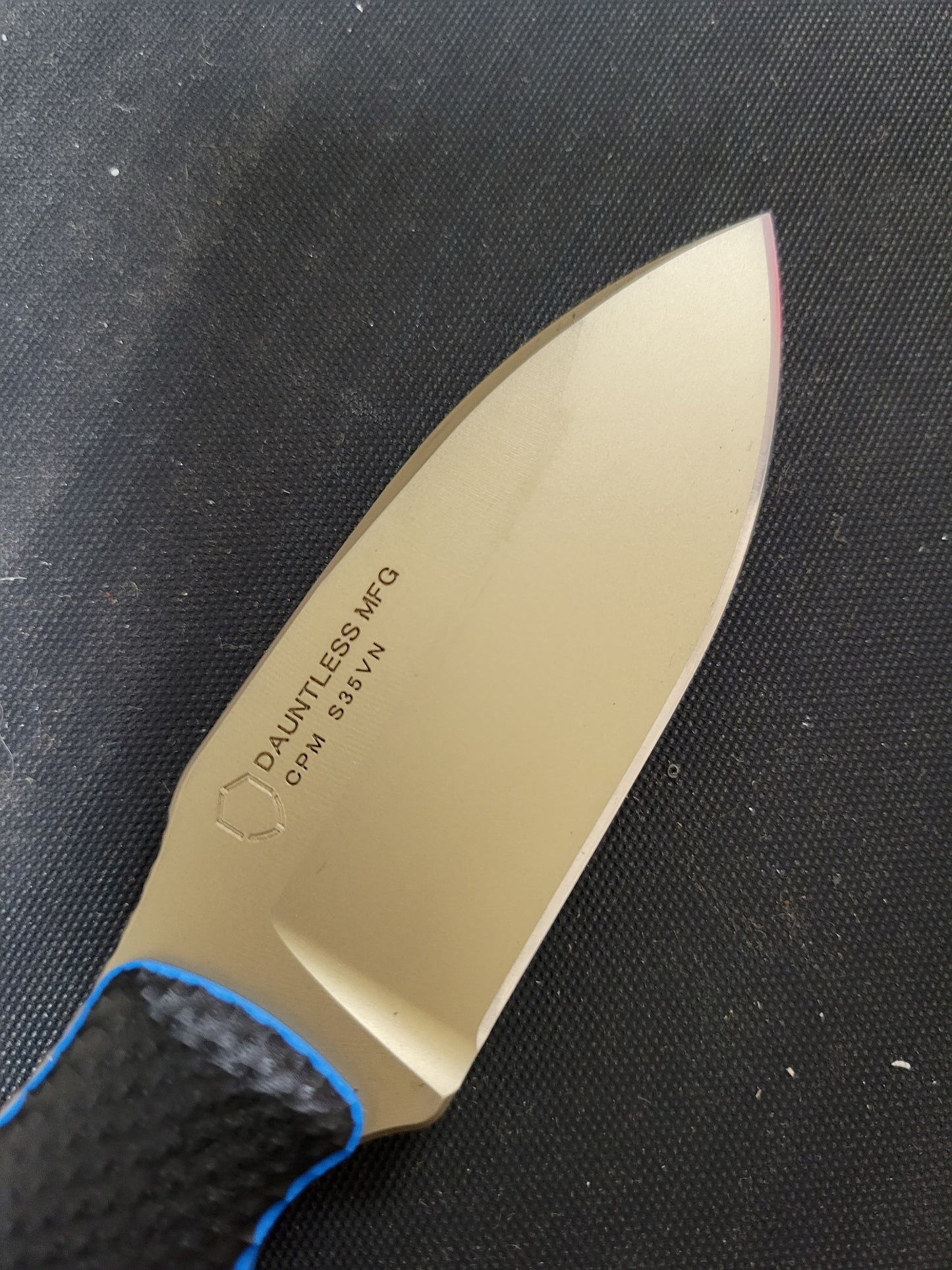

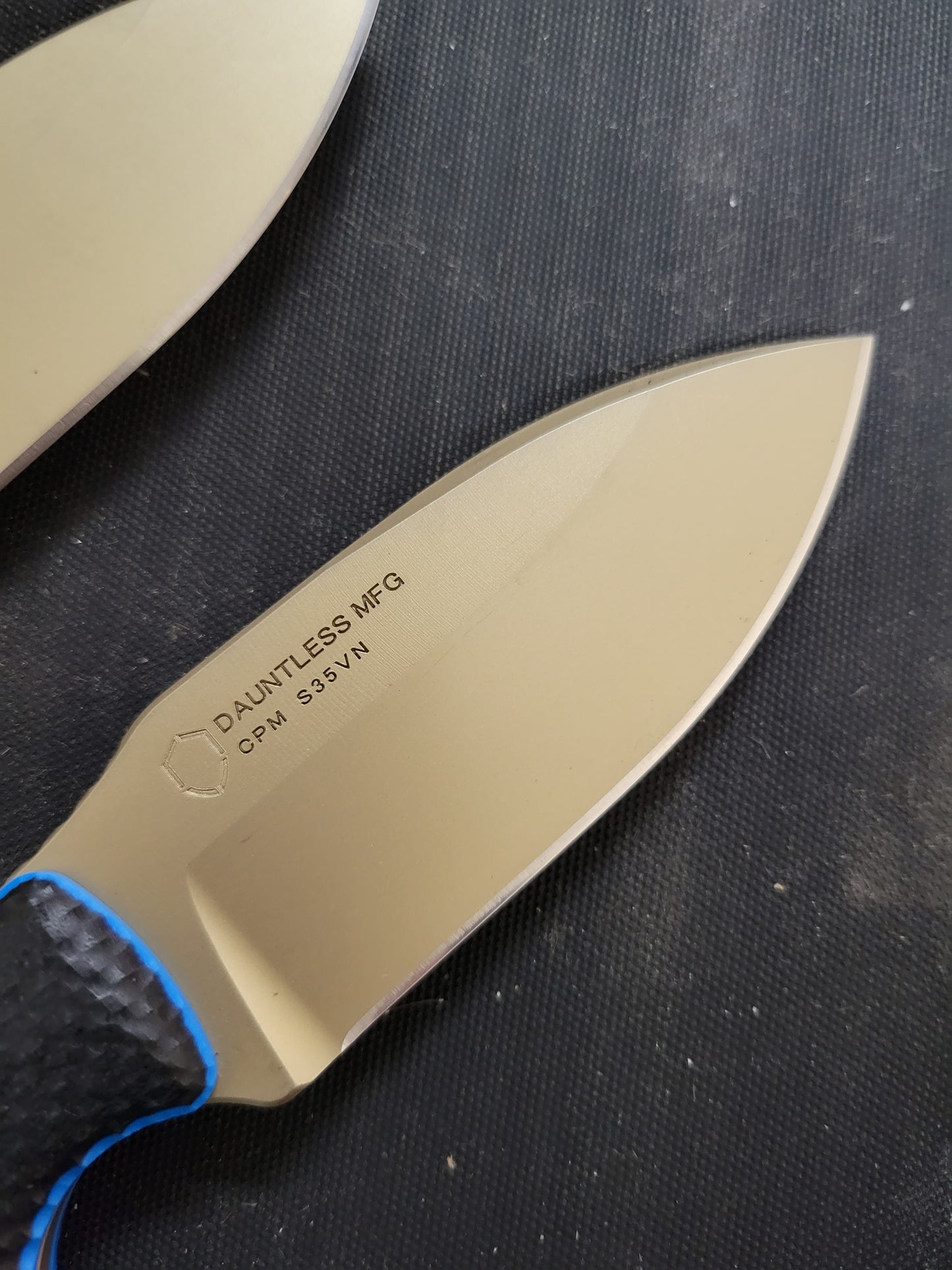

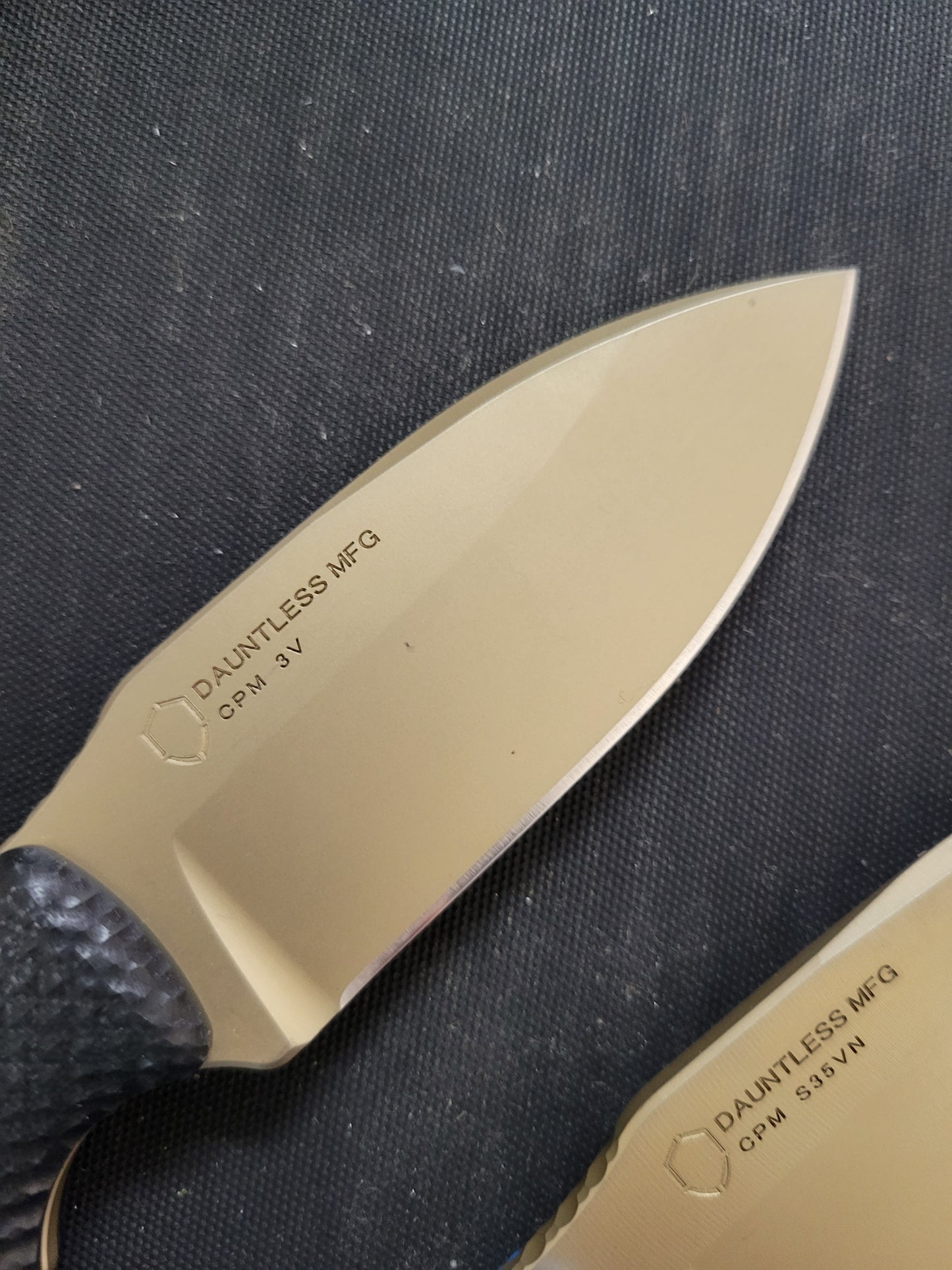

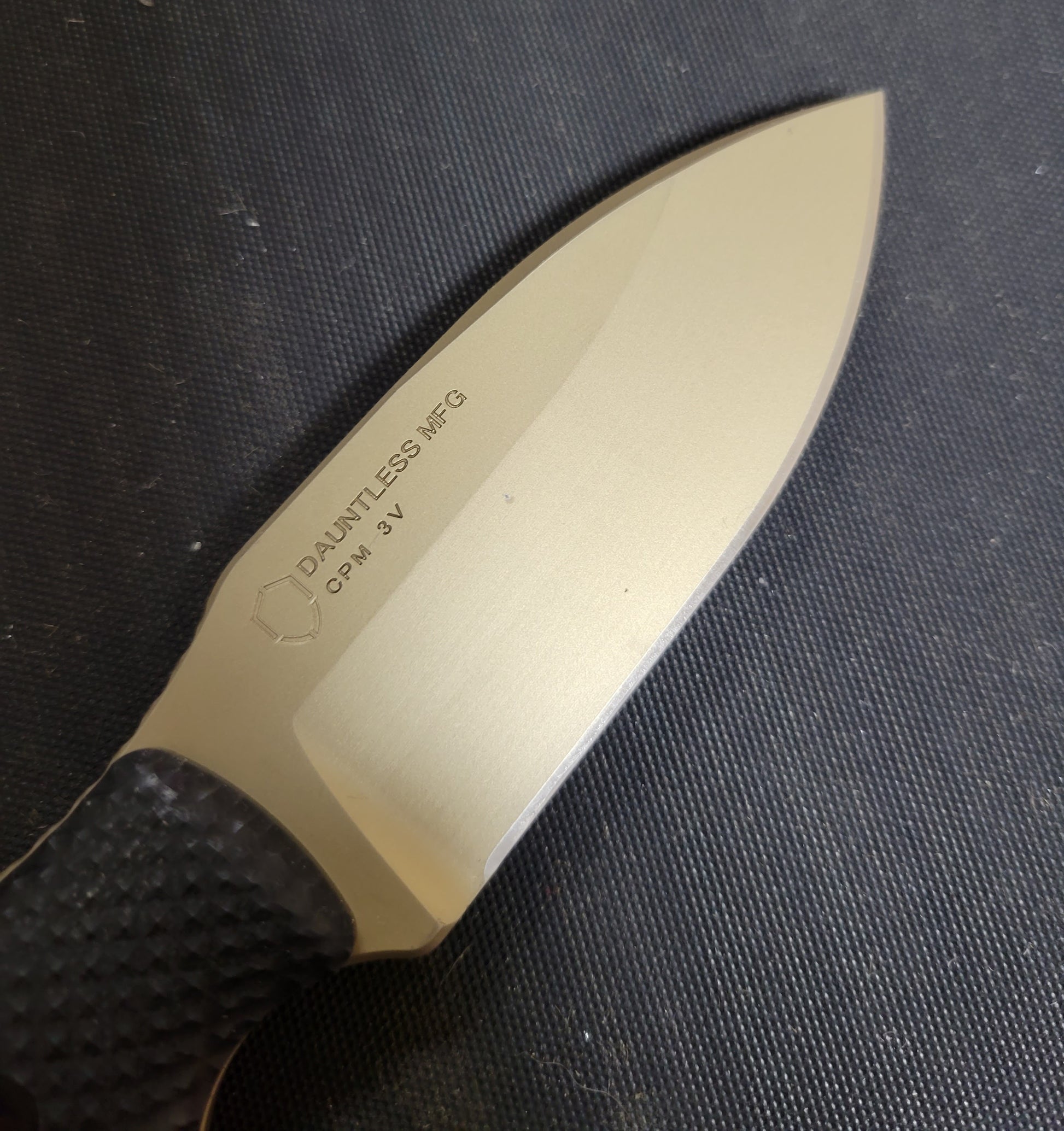

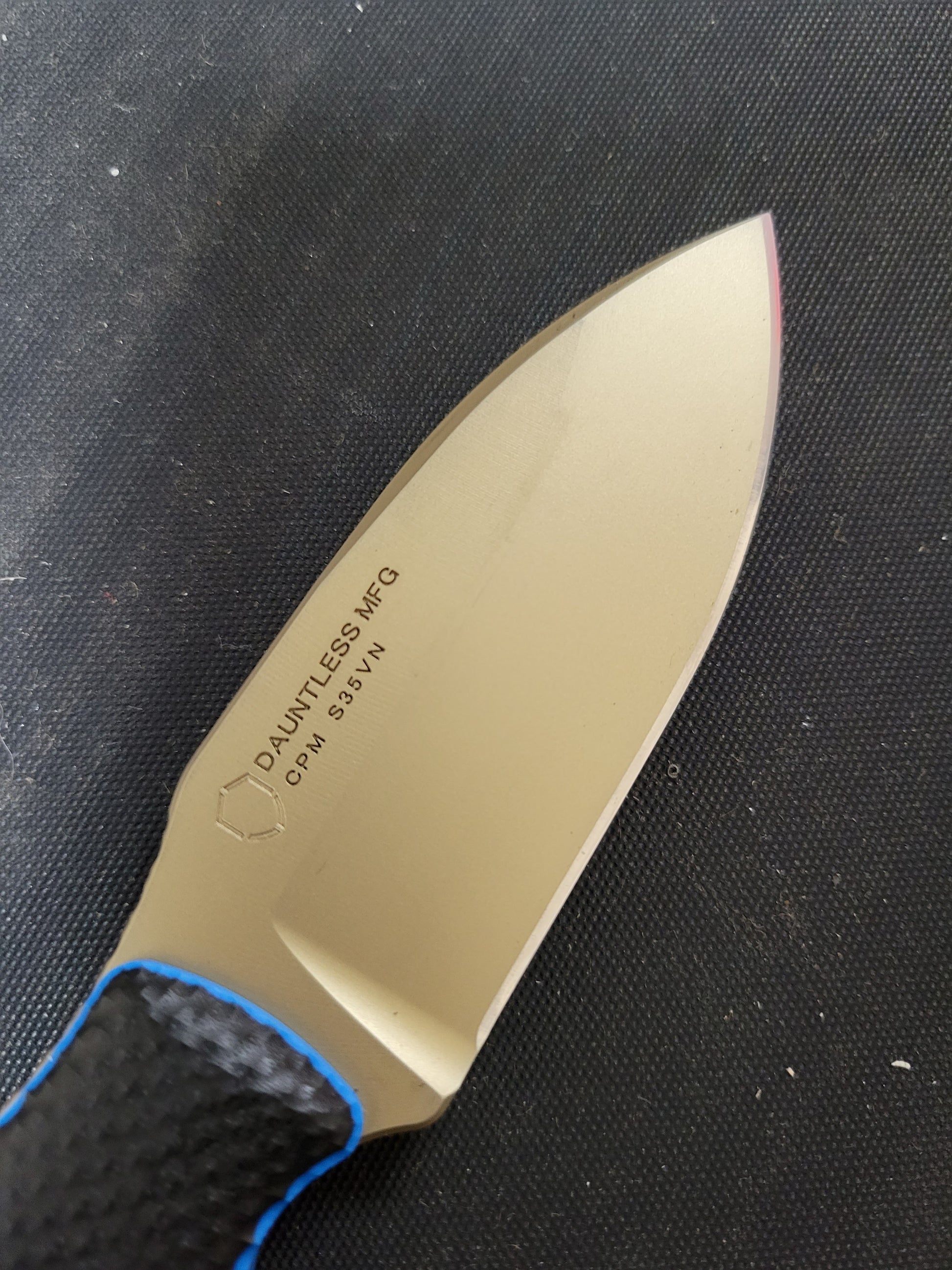

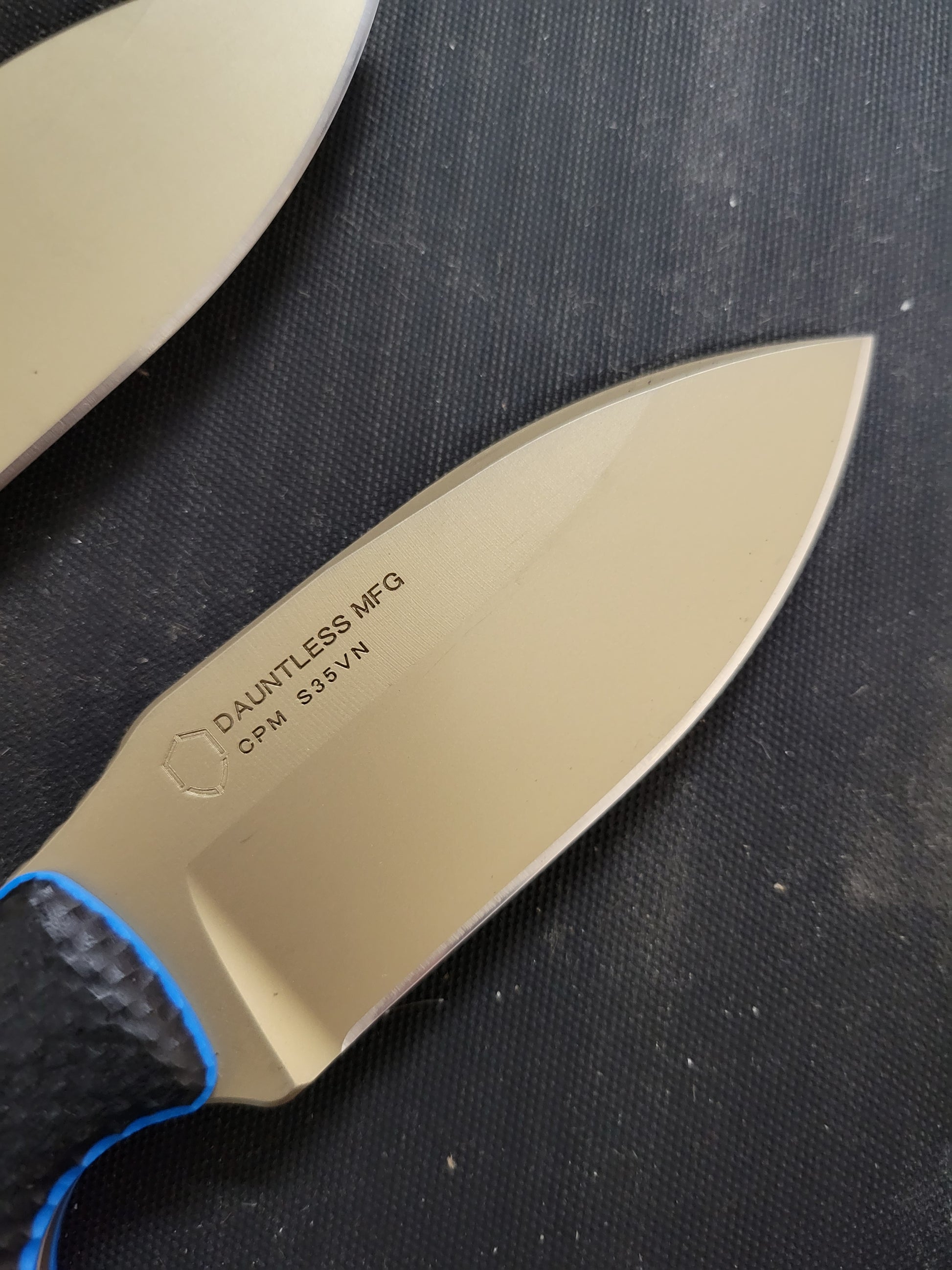

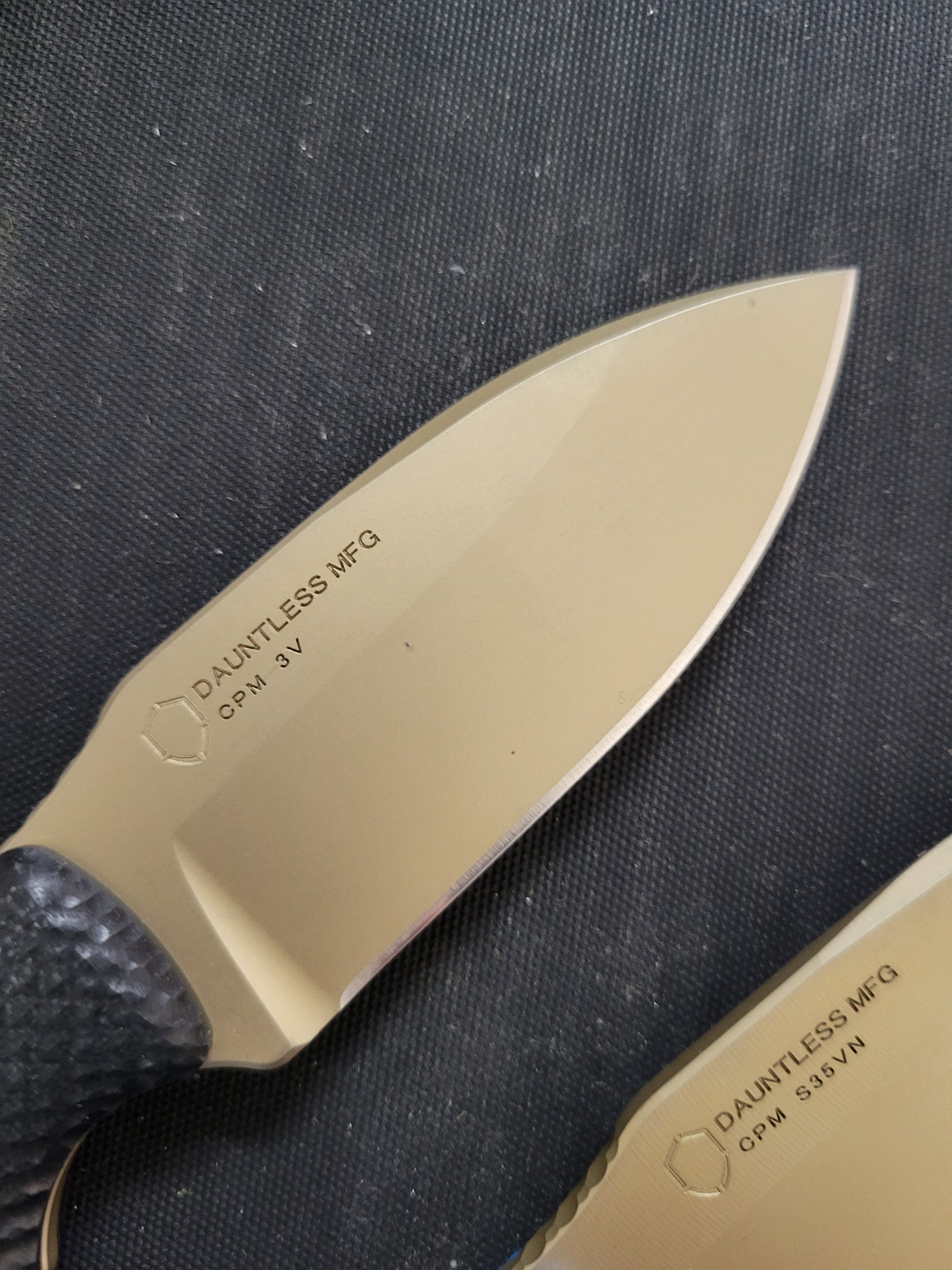

The Dogbone, our third collaboration with Matt Helm, is designed for exceptional everyday carry. Measuring 7" overall with a 3.1" blade and a 5/32" (0.156") thickness, this knife is made by us in the USA from high-quality steel. The blade is heat-treated to 60 HRc, except for Magnacut steel, which is treated to 63 HRc for enhanced performance.

Sheath

Each Dogbone knife comes with a precision-crafted, in-house manufactured sheath. It is available in both standard low-profile and deep-carry configurations, offering a variety of belt attachment methods. The standard low-profile sheath features adjustable retention, allowing you to fine-tune the fit to your preference. The sheath is constructed from .060" Kydex, vacuum-formed, CNC-trimmed, and assembled in-house. The top rivet holes use a common .75"/1.5" spacing to accommodate various attachment methods. All hardware is made of black oxide stainless steel. A leather sheath made by Chattanooga Leather Works is also available for purchase separately.

Steel Selection

- AEB-L: Known for its excellent edge retention and ease of sharpening, AEB-L is a high-carbon stainless steel that is both tough and corrosion-resistant, making it ideal for everyday use.

- 80CrV2: A tough, high-carbon steel favored for its durability and edge stability. It’s particularly well-suited for heavy-duty tasks.

- Magnacut: A premium stainless steel that balances hardness, toughness, and corrosion resistance, with the added benefit of being heat-treated to 63 HRc for superior performance.

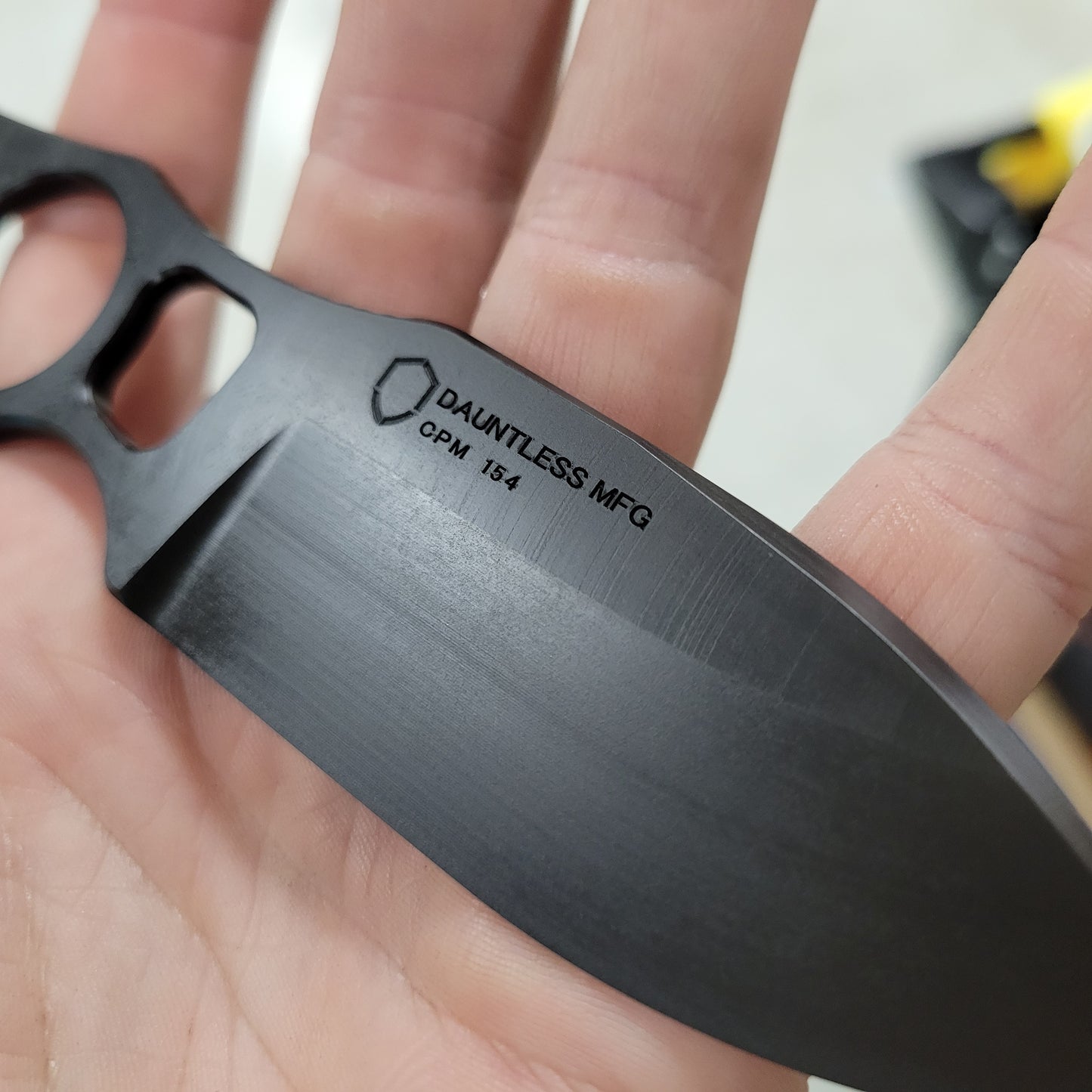

- CPM 3V: An exceptionally tough steel that holds a fine edge through hard use, ideal for heavy-duty tasks.

Blade Finishes

- Magnacut: Available in Tumbled or Black Oxide finishes.

- CPM 3V: Available in Black Nitride finish.

- 80CrV2: Available in Black Oxide finish.

- AEB-L: Available in Satin Bead Blasted Stainless finish.

Jimping

- Matt Helm Signature Jimping: Features overlapping conical milled patterns, closely resembling the fine jimping found on Matt Helm's custom knives.

- Dauntless Standard Jimping: Aggressive semi-circular milled features arranged in a series, enhancing grip and control.