-

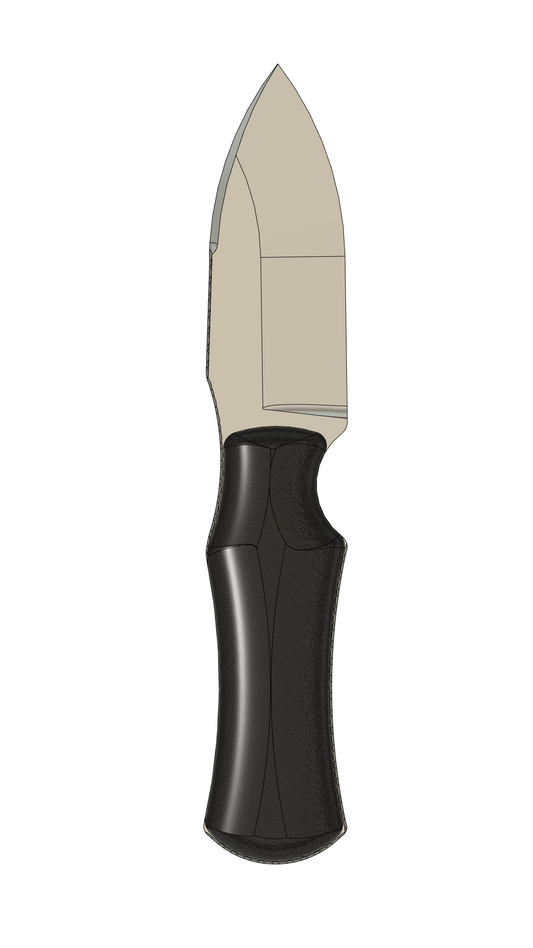

Matt Helm Dogbone

Regular price From $318.00 CADRegular priceUnit price per -

Matt Helm Work Knife V1

Regular price From $302.00 CADRegular priceUnit price per -

Matt Helm Work Knife V2

Regular price From $302.00 CADRegular priceUnit price per -

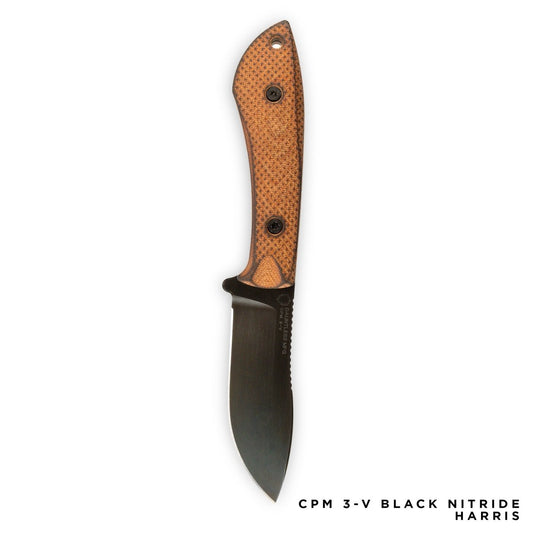

The Harris

Regular price $408.00 CADRegular priceUnit price per -

The Hiker F.I.D.O.

Regular price From $98.00 CADRegular priceUnit price per -

F.I.D.O. Sheath

Regular price $43.00 CADRegular priceUnit price per -

Sold Out

Sold OutThe EOD F.I.D.O.

Regular price $366.00 CADRegular priceUnit price per